Magnetron sputtering systems continue to play a large role in the thin film industry. Further advancements are to technologies are progressing rapidly.

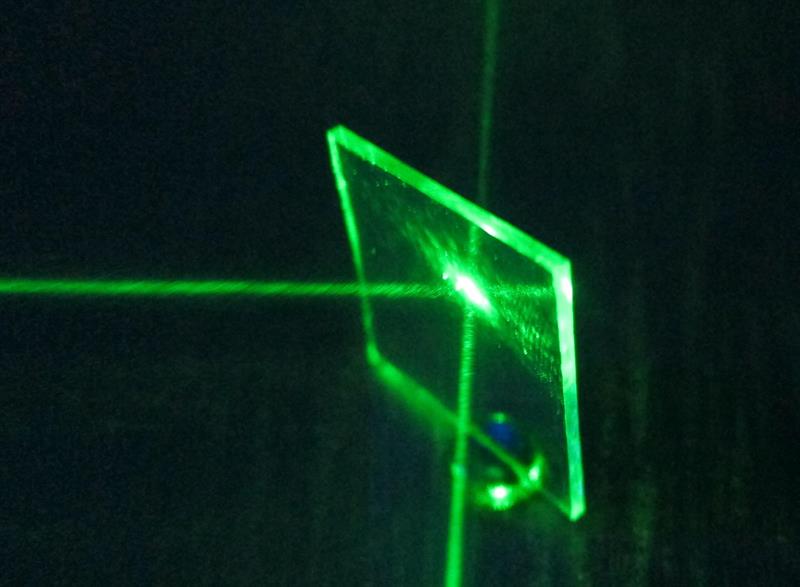

Magnetron sputtering is one of the essential strategies to prepare different sorts of films, for example, metal, semiconductor and cover films. The film thickness consistency is a pivotal variable for optical and electrical applications.

Magnetron sputtering is one of the essential strategies to prepare different sorts of films, for example, metal, semiconductor and cover films. The film thickness consistency is a pivotal variable for optical and electrical applications.

Studies and Research

To create top notch films on an large depositing territory, a ton of hypothetical and tests investigate the consistency to control the procedure all the more productively. In film manufacturing, handling it requires close consideration on such viewpoints as deposition rate, process soundness and also the use rate of target materials and shape, which requires the enhanced configuration of entire framework. The qualities of a magnetron sputtering system framework which has more than one framework with a specific target has been studied extensively in regards to output.

Nonetheless, the connection between the thickness of thin films with this framework and the thickness of square targets are still under constant research in the hopes of correlating the two together.

Correlations

It has been demonstrated through various tests that the thickness consistency of films by magnetron sputtering framework at the ideal proportion estimation of Wz/Wg 0.5 is prevalent over conventional framework which with 0.3 of thickness relative deviation at coordinative conditions. Additionally, the relative deviation was dropped as the option of separation from substrate to target. The outcomes were in accord with what was obtained experimentally. Although PECVD and magnetron sputtering systems have come a long way in the industry, there is still a substantial amount of discoveries that are just waiting to be uncovered.

Denton Vacuum, LLC supplies the highest quality sputter deposition system equipment on the entire web. If you are in need of a new piece of equipment, look no further than Denton Vacuum, LLC.